Introduction to the Unimig Viper Series

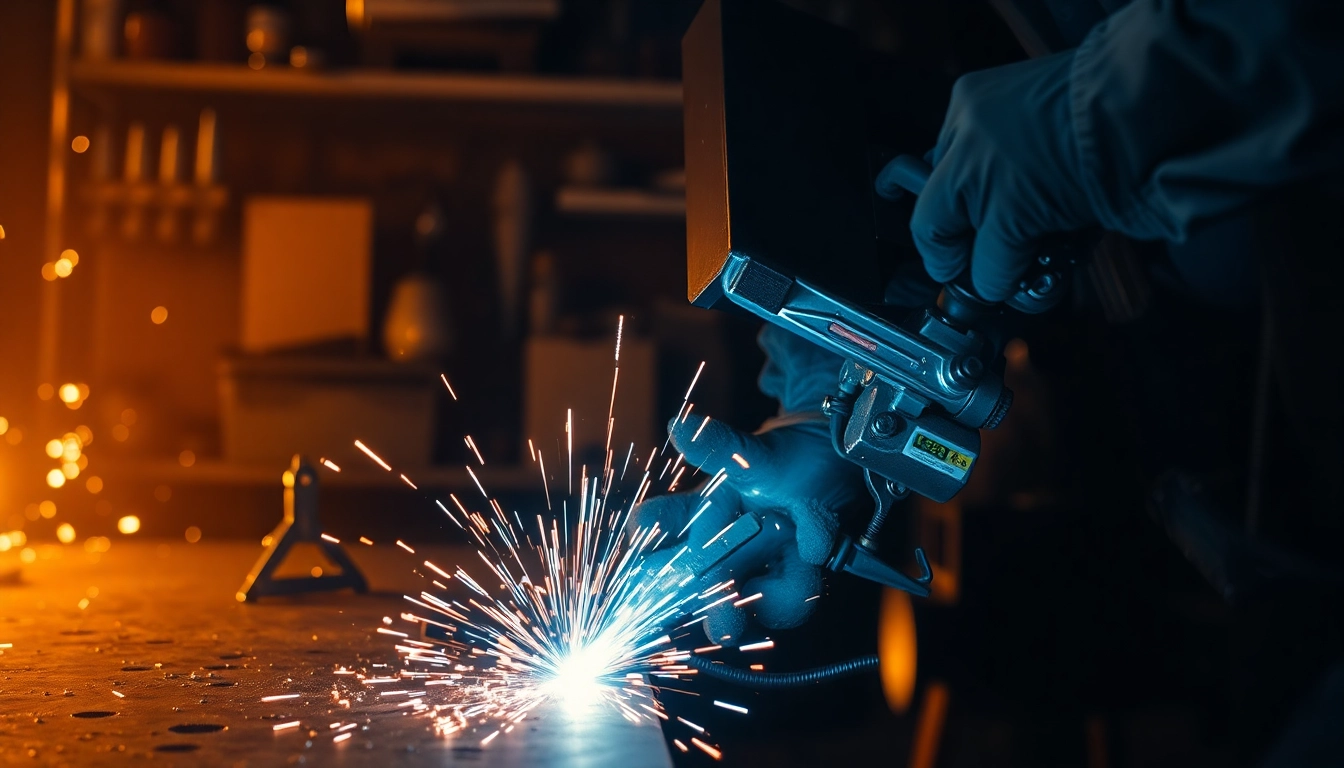

The unimig viper series represents a significant step forward in welding technology, blending versatility with ease of use. Designed for both professionals and DIY enthusiasts, the Viper series allows users to perform MIG, TIG, and Stick welding with a single compact machine. This article delves into what makes the Unimig Viper unique, analyzes its features and applications, and provides insights into effectively operating and maintaining this all-in-one welder.

What is the Unimig Viper?

The Unimig Viper is a multi-process welding machine that supports MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and Stick welding capabilities. This flexibility makes it an excellent choice for various welding projects, from metal fabrication to repair work. The Viper series is particularly praised for its portability and user-friendly design, making it highly suitable for home workshops and fieldwork alike.

Key Features of the Unimig Viper 185

The Unimig Viper 185 is a standout model within the Viper series, boasting several features that enhance its usability:

- Multi-process Capability: The Viper 185 can seamlessly switch between MIG, TIG, and Stick welding, offering versatility for a wide range of applications.

- Portability: Weighing only 20kg, this welding machine is easy to transport, making it ideal for on-site jobs.

- Inverter Technology: This technology ensures a stable arc and efficient operation, allowing users to weld thinner materials without burning through.

- Synergic Control: The welder features synergic settings that automatically adjust parameters based on the user’s selections, simplifying the welding process.

- Digital Display: An easy-to-read digital screen provides real-time information on welding settings, including voltage and wire speed.

Comparing Unimig Viper to Competitors

In the competitive landscape of welding machines, the Unimig Viper series holds its ground against several notable competitors like the Razor and Lincoln Electric welders. While some rivals may boast higher maximum outputs, the Viper 185 excels in versatility and user-friendliness. Additionally, the average rating of Unimig welders stands at an impressive 4.8 stars, reflecting substantial customer satisfaction. The Viper series, especially, is tailored to meet the needs of hobbyists and professionals seeking a reliable multi-process welder.

Understanding MIG, TIG, and Stick Welding

Basics of MIG Welding

MIG welding, or Metal Inert Gas welding, is a process that uses a continuous feed of wire to create an electrical arc between the wire and the workpiece. This arc melts both the wire and the base metal, forming a weld. One of the most significant advantages of MIG welding is its speed and ease of use, which makes it suitable for beginners and large production runs alike. The Viper 185 is particularly effective in MIG welding applications due to its precise wire speed control.

Advantages of TIG Welding

TIG welding offers a higher level of control than MIG and is ideal for thin materials or intricate work. It uses a non-consumable tungsten electrode to produce the weld. One of the key benefits of TIG welding is that it allows for greater artistry and precision, making it popular in industries like aerospace and automotive. With the Unimig Viper, welders can switch to TIG mode with ease, thanks to the seamless design and intuitive controls.

When to Use Stick Welding

Stick welding, also known as Shielded Metal Arc Welding (SMAW), is particularly effective for outdoor applications due to its resistance to wind and contamination. It involves using a stick electrode that produces a protective gas shield while welding. The Unimig Viper makes this transition easy, providing welders with the flexibility to choose the most appropriate method based on their project’s requirements.

Choosing the Right Unimig Viper Model for Your Needs

Assessing Your Welding Projects

When selecting the right Unimig Viper model, it’s vital to assess your specific welding projects. Consider factors like the materials you’ll be working with, your overall welding experience, and the thickness of the metals you’ll be joining. The Viper 185 excels in a variety of materials, including mild steel, stainless steel, and aluminum, making it a robust choice for many applications.

How to Select Between Viper Models

The Unimig Viper series includes several models, from the compact Viper 120 to the robust Viper 195. When selecting between them, factor in the maximum output required for your projects. For example, the Viper 185 provides 185 amps, striking a balance between performance and affordability, while the Viper 195 offers higher output for more demanding jobs.

Price Comparison and Value

In terms of price, the Unimig Viper series presents an excellent value proposition. While prices may vary depending on the model, they generally sit at competitive rates compared to other brands offering similar capabilities. The long-term durability and versatility of the Viper series contribute to its value, as it can serve multiple welding purposes without the need for additional machines.

Operating the Unimig Viper: A Step-by-Step Guide

Setting Up Your Welder

Setting up the Unimig Viper is straightforward. Begin by placing the machine in a well-ventilated area and ensuring it is connected to a suitable power source. Attach the appropriate torch and clamp for your chosen welding method, whether it be MIG, TIG, or Stick. Adjust the settings on the digital display according to the material and thickness you will be welding, and perform a test weld to ensure your settings are correct.

Common Techniques for Beginners

For beginners, mastering a few essential techniques can lead to successful welding results. One important technique is understanding travel speed—the speed at which you move the welder along the joint. Maintaining a consistent speed helps produce even weld beads. Additionally, practicing the correct angle of the torch while welding is crucial; a 15-degree angle usually yields the best results for most applications.

Troubleshooting Common Issues

Even experienced welders face challenges. Common issues such as poor arc stability, inconsistent weld beads, or excessive spatter can often arise. For arc stability, check that your settings match the wire diameter and material thickness. If weld beads are inconsistent, ensure that your travel speed remains steady and that the workpiece is clean. Regularly replacing worn-out tips and consumables will also mitigate these issues.

Maintenance and Care for Your Unimig Viper

Essential Maintenance Tips

Caring for your Unimig Viper is essential to ensure its longevity and reliable performance. Regularly clean the machine by removing dust and debris from the casing. Inspect cables for wear and replace any damaged components immediately. Additionally, periodic recalibration of the settings may be necessary to maintain optimum performance, especially if you switch between different welding projects.

Replacing Parts and Accessories

Over time, certain parts of your Unimig Viper will experience wear and tear. Commonly replaced items include the welding torch, liner, and contact tips. It’s vital to use genuine parts from the manufacturer to ensure compatibility and performance. Refer to the user manual for specific guidelines on maintaining and replacing these components to avoid potential damages.

Extending the Lifespan of Your Welder

To extend the lifespan of your Unimig Viper, always store it in a dry location away from extreme temperatures and moisture. Regular maintenance checks, proper handling, and timely replacements of consumable parts will also significantly contribute to the longevity of your machine. Following these practices not only ensures optimal performance but also maximizes your investment.